CPU makers are experimenting with different substrates to double clock speeds

Backside line: Warmth is a pc’s worst enemy, and the most recent batches of cutting-edge CPUs rolling off meeting strains are among the many hottest ever produced. It is a pattern that is merely not sustainable for for much longer, and Silicon Valley is effectively conscious. Thankfully, a few of the world’s high chipmakers are already experimenting with a wide range of supplies that might considerably decrease working temperatures.

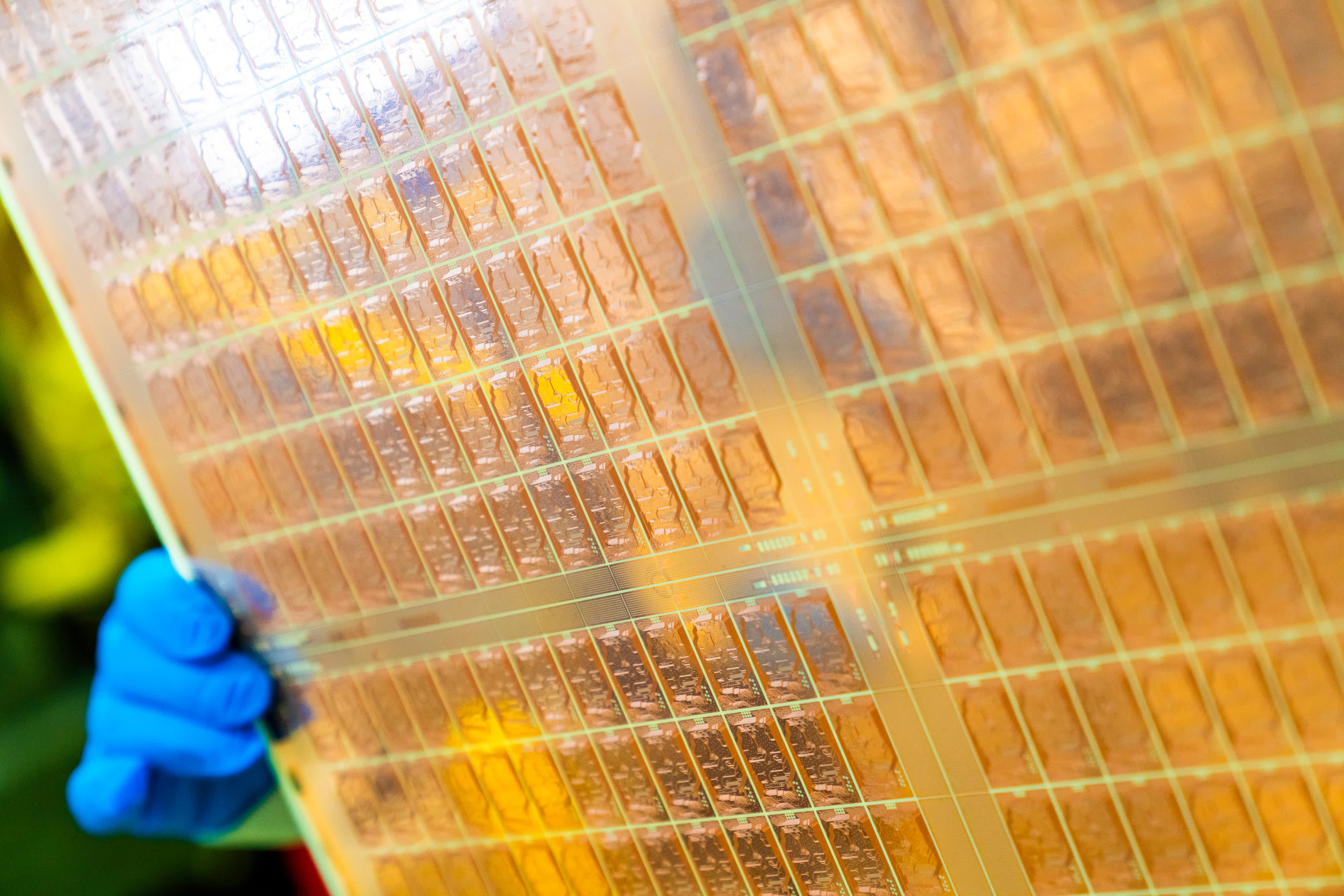

Diamond Foundry, which makes lab-grown artificial diamonds in San Francisco, is main the cost. The outfit has produced tons of of four-inch-wide artificial diamond wafers measuring lower than three millimeters thick. The concept is to exchange a few of the inactive silicon in a conventional microchip with a layer of artificial diamond, which is a superb conductor of warmth.

Martin Roscheisen, Diamond Foundry CEO, instructed The Wall Street Journal that chips utilizing their artificial diamond wafer can function at a minimal of twice their rated clock pace with out failing. Within the lab, firm engineers have even reportedly managed to get certainly one of Nvidia’s strongest chips to run at 3 times its base clock.

Roscheisen stated Diamond Foundry is in talks with main chipmakers, EV makers, and protection contractors to assist enhance chips and electronics. Key to additional exploring this avenue, Roscheisen added, is the falling price to fabricate artificial diamonds.

Diamond Foundry is not the one alternate chip substrate maker on the town. An organization named Coherent makes polycrystalline diamond wafers whereas one other referred to as Element Six presents bigger items that can be utilized between chips and heatsinks.

In September, Intel launched a glass substrate for next-gen packaging that it has been engaged on for greater than a decade. In comparison with fashionable natural substrates, glass has higher thermal, bodily, and optical properties which translate to an interconnect density enhance of as much as 10x. Glass additionally presents 50 p.c much less sample distortion with enhanced flatness that improves depth of focus for lithography.

Intel on the time stated it hopes to ship its first full glass substrate options beginning within the second half of this decade.