Scientists design miracle material that turns inflexible on the push of a button

Briefly: Scientists have designed a wearable textile that may go from smooth to inflexible straight away and will quickly be making its method into medical braces, robotic limbs, and way more. The form-shifting materials, known as RoboFabric, was cooked up by a group at Singapore’s Nanyang Technological College. Taking inspiration from the interlocking scales of pangolins and armadillos, the researchers designed a community of 3D-printed tiles related by steel fibers working via tiny channels between them.

When the fibers are unfastened, the tiles can transfer freely just like the hyperlinks of a sequence. However once they contract, the tiles lock collectively right into a sturdy construction that is over 350 occasions extra inflexible.

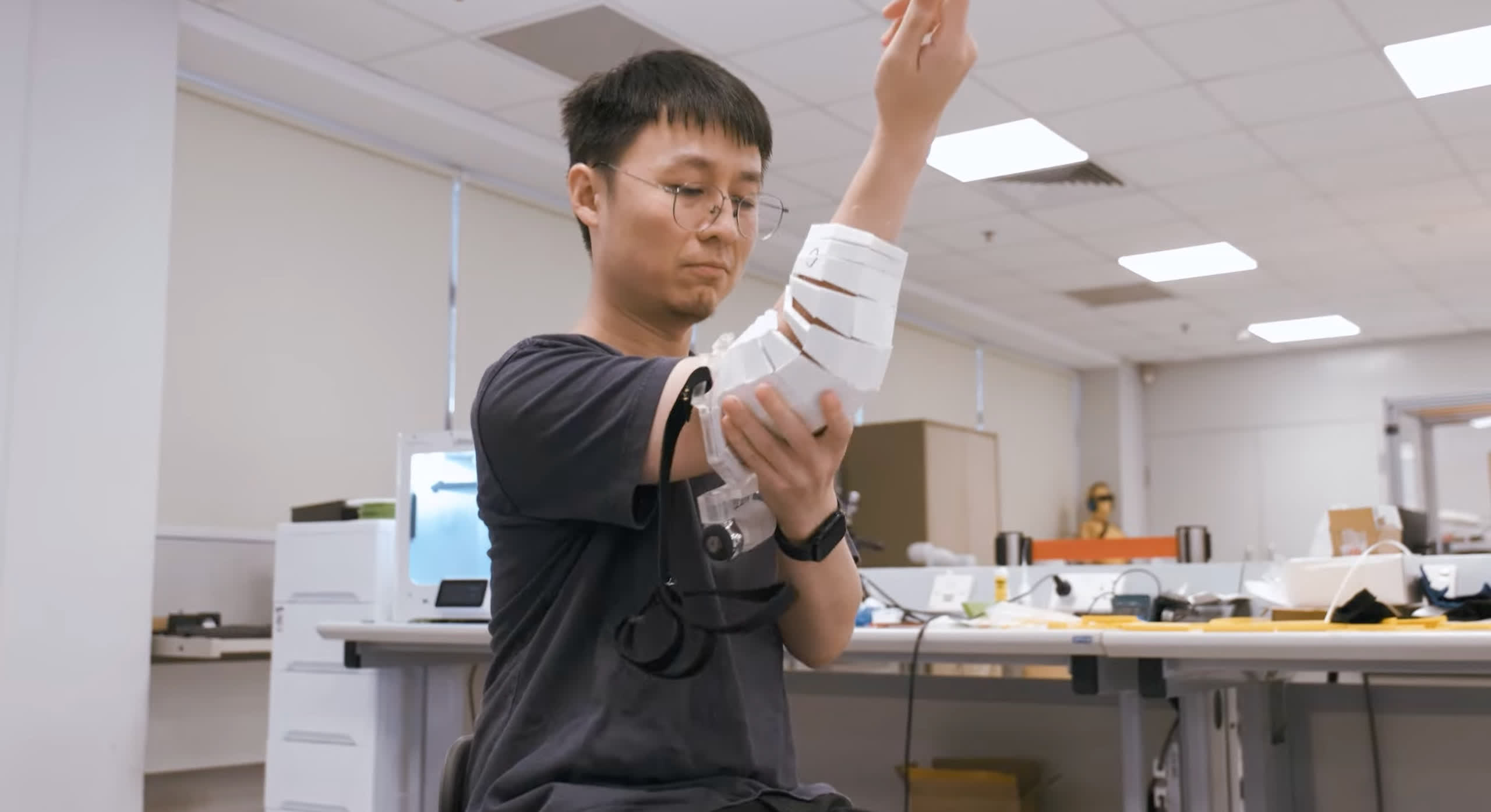

The group discovered it might scale back the muscle energy wanted to elevate a weight by as much as 40%. This might are available notably helpful for people with motion issues like Parkinson’s, serving to stabilize the motion trajectory so there’s much less shaking. Think about an elbow or wrist brace that helps your joints on demand as you are transferring heavy objects. The researchers additionally note that it may be tailored for “knee purposes” to enhance gait patterns and forestall falls.

“We envision that in future, sufferers who want a plaster solid for fractures would have the choice of customising a versatile limb help that’s fabric-like earlier than stiffening,” explains lead scientist Yifan Wang. “In contrast to typical inflexible and unremovable casts, they’d even be straightforward to placed on or take away on the contact of a button. In day by day use, joint helps may also assist the aged of their day by day duties, serving to to cut back the muscle power wanted for heavier hundreds.”

Making one among these shape-shifting braces begins with a 3D scan of the wearer’s arm or leg. Software program dissects the 3D mannequin into dozens of geometric tiles that may be 3D printed in about an hour. Metallic cables are then threaded via channels between the tiles by hand, though the group does plan to automate the method. These cables connect with an digital gadget to tighten or loosen them as wanted.

The medical purposes are simply the beginning. Within the analysis paper, Wang’s group showed that when RoboFabric is sealed into an elastic pores and skin, it will probably transition between a versatile state and a stiff state by making use of or eradicating vacuum stress. They turned it right into a small, worm-like ‘smooth robotic’ that may crawl, swim, and even type a protecting shell on demand.

“These capabilities are essential for exploration and rescue robots that want to maneuver in complicated terrains and supply safety on demand,” the researchers famous.

Maybe the good demo concerned equipping a drone with 4 such robots created from the material appearing as grippers. When floppy, the grippers fold up into the drone physique. When made inflexible, they perform as grabbing claws that may snatch objects or cushion onerous landings. It is an ingenious technique to make drones extra versatile with out sacrificing aerodynamics.

With these prototypes accomplished, the NTU group is now in search of trade companions to place their miracle material via its paces.